What is Pipe Bending Machine and How It Works?

What is Pipe Bending Machine and How It Works?

Pipe bending machines are specialized tools designed to bend pipes and tubes into specific shapes and angles without compromising the integrity of the material. These machines are crucial in industries such as construction, automotive, aerospace, and manufacturing.

Table of Contents

- Introduction

- Types of Pipe Bending Machines

- Key Components

- How It Works

- Applications

- Conclusion

Introduction

Pipe bending machines allow for the precise bending of pipes and tubes, which is essential for creating components used in various industrial applications. These machines can handle different materials, including steel, copper, aluminum, and other alloys, and can produce complex shapes with high accuracy.

Types of Pipe Bending Machines

There are several types of pipe bending machines, each suited for different bending tasks and materials:

- Manual Pipe Bending Machines

These are hand-operated and suitable for small-scale projects or thin-walled pipes. They are commonly used in DIY applications and small workshops.

- Hydraulic Pipe Bending Machines

Hydraulic machines use hydraulic power to bend pipes and are capable of handling thicker and harder materials. They are ideal for medium to heavy-duty industrial applications.

- CNC Pipe Bending Machines

Computer Numerical Control (CNC) machines are automated and highly precise. They are used for complex and high-volume bending tasks, providing consistent and repeatable results.

- Electric Pipe Bending Machines

Electric machines use electric motors to drive the bending process. They offer a balance between manual and hydraulic machines in terms of power and ease of use.

Key Components

Regardless of the type, pipe bending machines share several essential components:

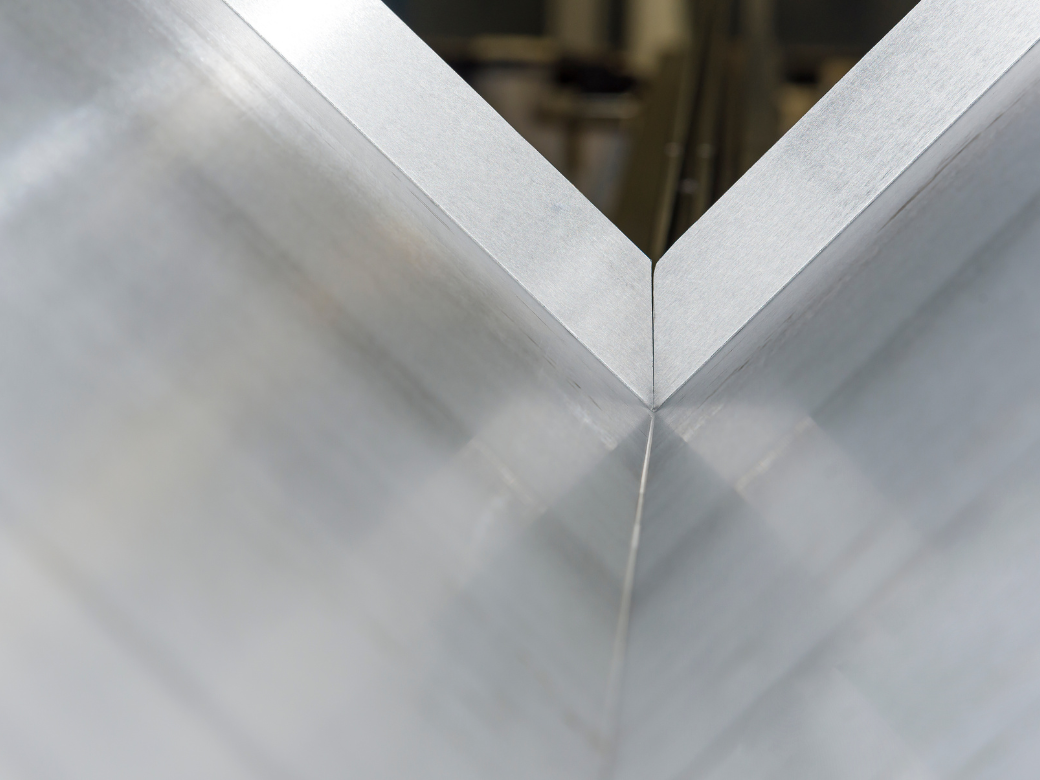

- Bending Die

The bending die is the part that shapes the pipe during the bending process. It is designed to match the desired bend radius and pipe diameter.

- Clamp Die

The clamp die holds the pipe in place and ensures it moves correctly during the bending process.

- Pressure Die

The pressure die applies force to bend the pipe around the bending die.

- Mandrel

In some machines, a mandrel is inserted into the pipe to prevent it from collapsing or deforming during the bend, especially for tight radius bends.

- Control System

For CNC and electric machines, the control system (which may include a computer interface) allows operators to input specific bending parameters for precision and repeatability.

How It Works?

The operation of a pipe bending machine involves several steps:

- Setup

- Select the appropriate bending die based on the pipe diameter and desired bend radius.

- Install the die and ensure all components are properly aligned and secured.

- Positioning the Pipe

- Insert the pipe into the machine and position it against the bending die.

- Secure the pipe using the clamp die to prevent movement during bending.

- Bending Process

- For manual machines, pull the handle to bend the pipe around the die.

- For hydraulic machines, activate the hydraulic system to apply pressure and bend the pipe.

- For CNC machines, program the desired bend parameters into the control system and start the automated bending process.

- Final Adjustments

- Inspect the bend for accuracy and make any necessary adjustments.

- Remove the bent pipe from the machine once the desired shape is achieved.

Applications

Pipe bending machines are used in a wide range of applications, including:

- Construction: Creating structural components like railings and frames.

- Automotive: Manufacturing exhaust systems and roll cages.

- Aerospace: Fabricating aircraft components.

- Manufacturing: Producing machinery and equipment parts.

Conclusion

Pipe bending machines are versatile tools essential for shaping pipes and tubes in various industries. Understanding the different types of machines and their components helps in selecting the right tool for specific bending tasks. Whether it’s a manual, hydraulic, CNC, or electric pipe bender, each type offers unique advantages and capabilities, making pipe bending efficient and precise.