Step-by-Step Instructions for Using a Bending Machine

Step-by-Step Instructions for Using a Bending Machine

Here’s an overview:

Introduction to Bending Machines

Types of Bending Machines

Safety Procedures for Operating a Bending Machine

Setting Up and Preparing the Bending Machine

Understanding the Bending Process

Troubleshooting Common Bending Machine Issues

Maintenance Tips for Bending Machines

Advanced Techniques for Operating a Bending Machine

Creating Complex Bends with a Bending Machine

Best Practices for Efficient Bending Machine Operations

Introduction to Bending Machines

- Bending machines are versatile tools used to shape metal sheets and pipes with precision.

- These machines come in various types, such as manual, hydraulic, or CNC, each catering to different bending needs.

- Understanding the basics of bending machines is crucial for achieving accurate and consistent bends.

- With the right setup and technique, bending machines can create complex shapes and angles efficiently.

- Safety precautions must be followed when operating bending machines to prevent accidents and ensure a smooth bending process.

Types of Bending Machines

There are four main types of bending machines commonly used in metalworking:

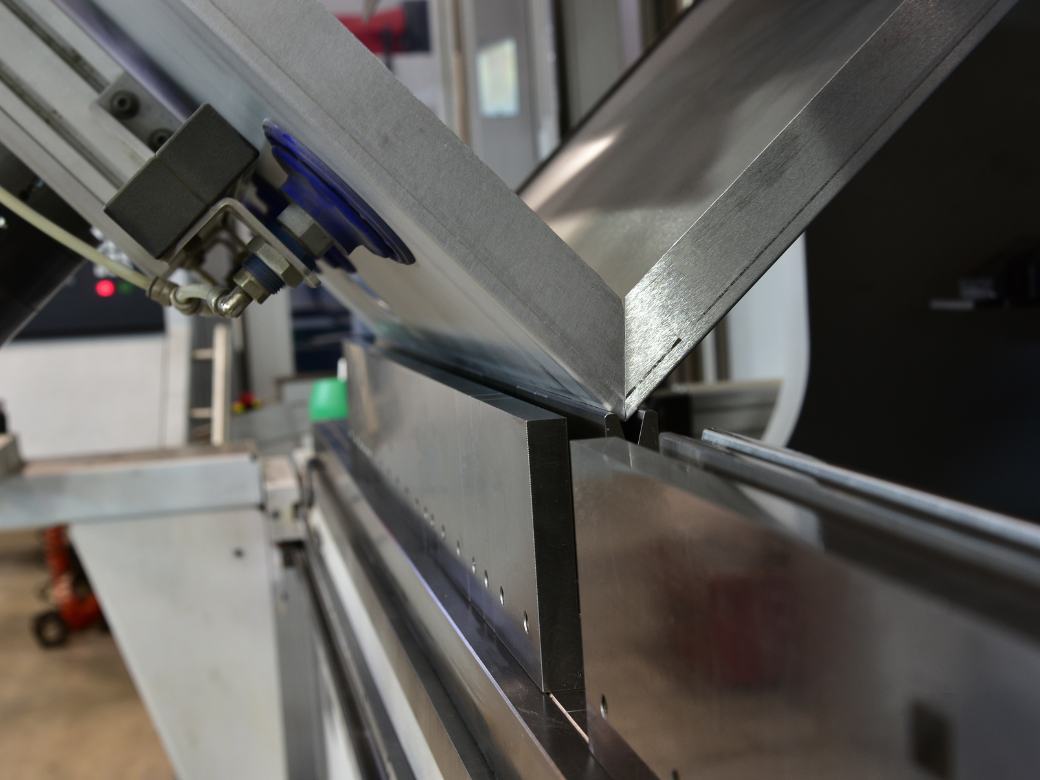

- Press Brake: A press brake is the most common type of bending machine. It uses a punch and die to bend the metal along a straight axis.

- Tube Bender: As the name suggests, a tube bender is specifically designed to bend tubes and pipes. It can create precise bends without damaging the tube.

- Roll Bending Machine: This type of machine is used to create curves and arcs in metal sheets. It gradually bends the metal by passing it through a series of rolls.

- Section Bending Machine: Also known as a profile bending machine, this tool is used to bend metal profiles and beams. It is commonly used in construction and manufacturing industries.

Each type of bending machine serves a specific purpose and is chosen based on the requirements of the metalworking project.

Safety Procedures for Operating a Bending Machine

- Wear Personal Protective Equipment (PPE): Ensure to wear safety glasses, gloves, and hearing protection to prevent injuries.

- Inspect the Machine: Prior to operation, check the machine for any visible damage or defects. Do not operate a faulty machine.

- Follow Operating Instructions: Familiarise yourself with the manufacturer’s guidelines for operating the bending machine safely and correctly.

- Secure Workpiece: Always secure the workpiece properly using clamps or fixtures to prevent it from moving during bending.

- Use Two-Hand Controls: When operating the machine, use both hands on the control buttons to ensure safe and controlled bending.

- Keep Hands Clear: Avoid placing your hands near moving parts of the machine during operation. Use tools or push sticks when necessary.

- Emergency Stop: Be aware of the emergency stop button location and how to use it in case of any unexpected situations.

- Training: Only trained personnel should operate the bending machine to minimise the risk of accidents.

Setting Up and Preparing the Bending Machine

- Ensure Proper Placement: Position the bending machine on a flat and stable surface to prevent any accidents during operation.

- Check Power Supply: Make sure the machine is connected to a suitable power source and that the power switch is in the off position before plugging it in.

- Adjust the Settings: Set the desired angle and radius on the bending machine according to the specifications of the job.

- Load the Material: Place the material to be bent securely in the bending machine, ensuring it is aligned correctly with the bending die.

- Test Run: Before starting the actual bending process, perform a test run with scrap material to ensure everything is set up correctly.

- Safety Gear: Always wear appropriate safety gear such as gloves and goggles to protect yourself during the bending process.

Understanding the Bending Process

- A bending machine uses force to shape metal sheets or tubes.

- The material is placed between the bending machine’s rollers.

- The machine exerts pressure, causing the material to bend.

- The operator controls the angle and degree of the bend.

- Different dies can be used to achieve various bending shapes.

- Understanding the properties of the material is crucial for successful bending.

- Bending radius and bend allowance calculations are essential for accuracy.

- Practice and experimentation help in mastering the bending process.

Troubleshooting Common Bending Machine Issues

- Uneven Bends:

- Check the alignment of the material in the machine.

- Ensure the tooling is installed correctly and not worn out.

- Adjust the machine settings for more uniform bends.

- Cracks or Tears in the Material:

- Slow down the bending process to reduce stress on the material.

- Check the material thickness and adjust the machine settings accordingly.

- Machine Not Powering On:

- Check the power source and ensure it is properly connected.

- Inspect the machine’s electrical components for any issues.

- Reset the machine according to the manufacturer’s guidelines.

- Irregular Bends:

- Verify that the material is positioned correctly in the machine.

- Check for any obstructions or debris that may be affecting the bending process.

- Calibrate the machine according to the instructions in the manual.

Maintenance Tips for Bending Machines

- Regularly inspect the machine for any signs of wear and tear.

- Keep the machine clean and free of dust and debris.

- Lubricate moving parts as recommended by the manufacturer.

- Check and replace any worn-out or damaged components.

- Calibrate the machine regularly to ensure accurate bending.

- Train operators on proper machine use and maintenance practices.

- Store the machine in a dry and secure location when not in use.

Advanced Techniques for Operating a Bending Machine

- Utilize different tooling attachments for complex bends.

- Experiment with various bending speeds to achieve desired results.

- Implement back-gauges and reference points for precise bends.

- Explore the use of custom-made bending dies for unique shapes.

- Familiarize yourself with multi-step bending processes for intricate designs.

Creating Complex Bends with a Bending Machine

- Understand the capabilities of your bending machine before attempting complex bends.

- Use the appropriate tooling and die sets for the specific bend requirements.

- Adjust the machine settings for bend angle, bend radius, and material thickness.

- Secure the material firmly in place to prevent slippage during the bending process.

- Gradually feed the material through the machine while maintaining a consistent speed.

- Check the bend quality periodically and make adjustments as needed.

- Practice caution when creating intricate bends to avoid material distortion or machine damage.

Best Practices for Efficient Bending Machine Operations

- Safety First: Always wear appropriate personal protective equipment (PPE) such as gloves and goggles to prevent accidents.

- Material Preparation: Ensure materials are clean and free of any defects before bending to avoid damage to the machine or imperfect bends.

- Proper Tool Selection: Use the correct tooling for the job to achieve precise and accurate bends.

- Machine Setup: Follow the manufacturer’s instructions to set up the bending machine correctly for the material being used.

- Bend in Stages: For complex bends, perform multiple smaller bends rather than trying to achieve the final shape in one go.

- Regular Maintenance: Keep the bending machine well-maintained and lubricated to ensure optimal performance and longevity.

Operator Training: Train operators on how to use the bending machine safely and efficiently to improve productivity and reduce errors