How to Make a Bending Machine

How to Make a Bending Machine

Creating a bending machine involves a combination of mechanical skills, precision, and an understanding of the principles of metalworking. Whether you’re an enthusiast looking to start a DIY project or a professional seeking to customize a tool, this guide will walk you through the essential steps.

Table of Contents

Introduction

Materials and Tools Needed

Designing the Bending Machine

Building the Frame

Installing the Bending Mechanism

Testing and Adjustments

Conclusion

Introduction

A bending machine is an essential tool in metalworking, used to bend various types of metal into desired shapes. This guide aims to simplify the process of building a basic, manually operated bending machine. While advanced machines may require more complex components and automation, a manual bender can be created with basic materials and tools.

Materials and Tools Needed

Before beginning the construction, gather the following materials and tools:

Materials

- Steel bars and plates

- Bolts and nuts

- Springs

- Bearings

- Metal pipes

Tools

- Welder

- Angle grinder

- Drill press

- Measuring tape

- Wrenches

- Clamps

Designing the Bending Machine

Start with a clear design plan. Sketch a blueprint of your bending machine, focusing on the dimensions and the placement of each component. Consider the types of bends you will perform and ensure the machine can handle the metal thickness and width you intend to work with.

Key Components

- Frame: The sturdy base of the machine.

- Bending Arm: The lever arm used to apply force.

- Die and Roller: Components that shape the metal as it bends.

- Spring Mechanism: Ensures the arm returns to its original position.

Building the Frame

The frame is the backbone of your bending machine, providing stability and support.

- Cutting the Steel: Use an angle grinder to cut the steel bars and plates according to your design dimensions.

- Assembling the Frame: Weld the pieces together to form a rectangular base. Ensure all joints are secure and the frame is level.

- Adding Support: Weld additional steel bars diagonally to reinforce the frame.

Installing the Bending Mechanism

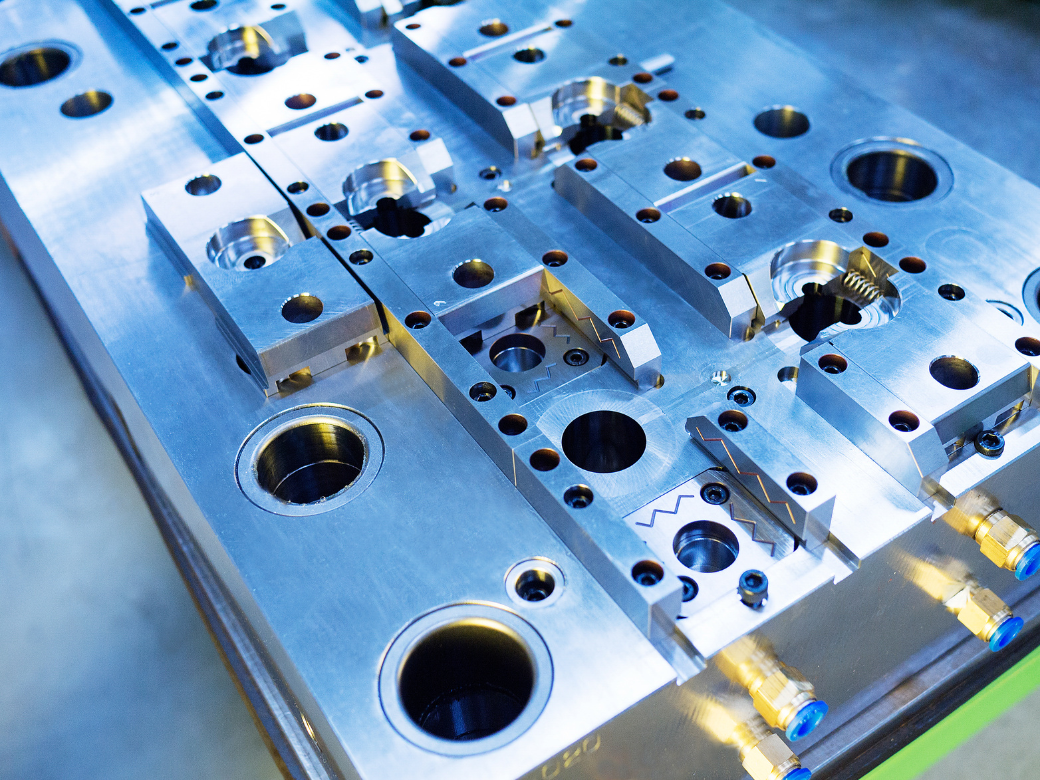

With the frame ready, install the bending mechanism, which includes the die, roller, and bending arm.

- Mounting the Die and Roller: Attach the die to the frame. Position the roller directly above it, ensuring it can move freely. Use bearings to reduce friction.

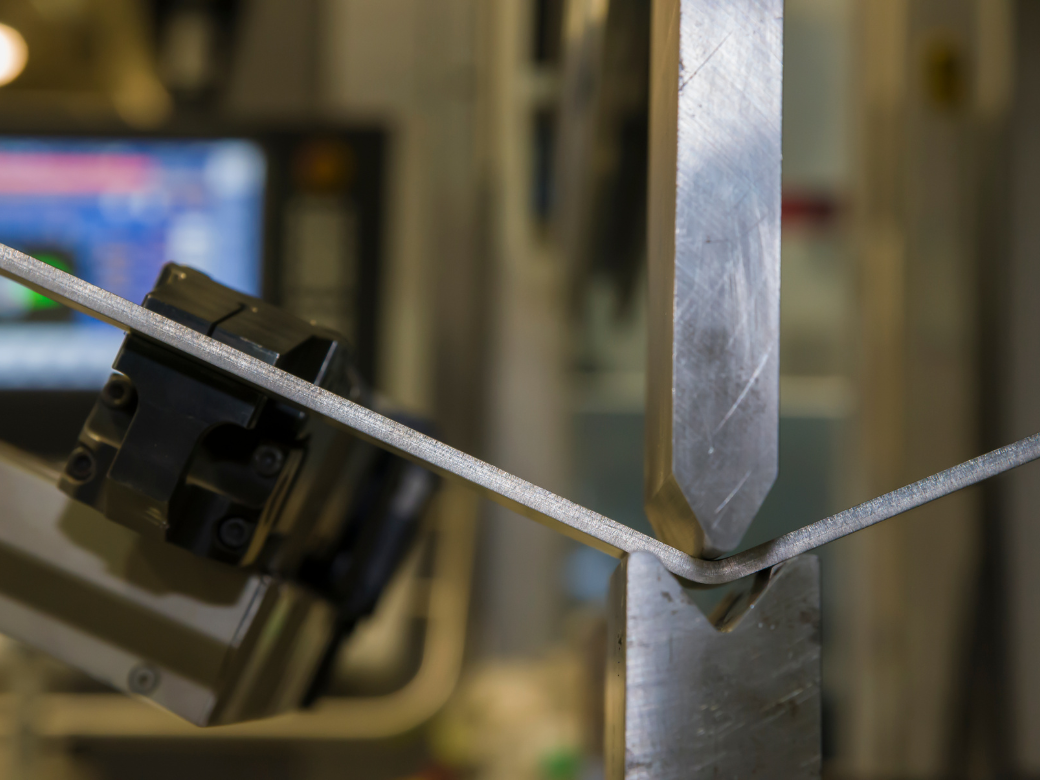

- Attaching the Bending Arm: Weld a steel pipe to form the bending arm. Ensure it is long enough to provide adequate leverage. Attach it to the frame with a pivot point using bolts and bearings.

- Spring Mechanism: Install a spring mechanism to return the bending arm to its original position. This can be done by attaching one end of a spring to the arm and the other to a fixed point on the frame.

Testing and Adjustments

Before using the machine for actual projects, it’s crucial to test it thoroughly.

- Initial Testing: Place a scrap piece of metal into the machine and slowly pull the bending arm to test its functionality. Ensure the metal bends as expected without excessive force.

- Adjustments: If the machine is not bending correctly, check for alignment issues, loose components, or inadequate leverage. Adjust the placement of the die and roller if necessary.

- Safety Check: Make sure all parts are securely fastened and there are no sharp edges or exposed moving parts that could pose a hazard.

Conclusion

Building a bending machine requires careful planning, precise execution, and thorough testing. By following this guide, you can create a functional and reliable tool for your metalworking projects. Remember to always prioritize safety, wear appropriate protective gear, and work in a well-ventilated area. Happy bending!