How Much is a Bending Machine?

How Much is a Bending Machine?

Purchasing a bending machine involves understanding the range of prices and the factors that influence these costs. Whether you’re looking for a basic manual bender or an advanced CNC machine, this guide will provide you with a comprehensive overview of what to expect in terms of pricing.

Table of Contents

- Introduction

- Types of Bending Machines

- Factors Affecting Price

- Price Ranges for Different Machines

- Additional Costs to Consider

- Conclusion

Introduction

Bending machines are essential tools in various industries, including metalworking, manufacturing, and construction. The cost of a bending machine can vary significantly based on its type, features, and capacity. Understanding these variables will help you make an informed purchasing decision.

Types of Bending Machines

Bending machines come in several types, each designed for specific applications and materials. Here are the most common types:

1. Manual Bending Machines

These are simple, hand-operated devices suitable for small-scale projects and thin materials. They are typically used in workshops and by hobbyists.

2. Hydraulic Bending Machines

These machines use hydraulic pressure to bend metal and are more powerful than manual benders. They are commonly used in medium to large-scale operations.

3. CNC Bending Machines

Computer Numerical Control (CNC) bending machines offer high precision and automation. They are used in industrial settings for complex and repetitive bending tasks.

4. Electric Bending Machines

Electric benders are similar to hydraulic machines but use electric motors. They offer a balance between manual and hydraulic machines in terms of power and precision.

Factors Affecting Price

Several factors influence the cost of a bending machine:

1. Type and Complexity

CNC and hydraulic machines are generally more expensive than manual or electric benders due to their advanced features and capabilities.

2. Capacity

Machines capable of bending thicker and wider materials cost more. The maximum bending capacity in terms of material thickness and width significantly impacts the price.

3. Brand and Quality

Reputable brands with a history of reliability and durability tend to price their machines higher. Quality of construction, warranty, and after-sales service also play a role.

4. Features and Automation

Advanced features such as programmable controls, multiple bending angles, and automation options increase the cost. CNC machines, with their high level of automation and precision, are among the most expensive.

5. Geographical Location

Prices can vary based on the region due to shipping costs, import duties, and local market conditions.

Price Ranges for Different Machines

Here is a general overview of the price ranges for various types of bending machines:

Manual Bending Machines

- Entry-level models: $100 – $500

- High-end models: $500 – $1,500

Hydraulic Bending Machines

- Small to medium-sized: $2,000 – $10,000

- Large industrial machines: $10,000 – $50,000

CNC Bending Machines

- Basic models: $20,000 – $50,000

- Advanced models: $50,000 – $150,000

- High-end, specialized machines: $150,000 and above

Electric Bending Machines

- Basic models: $1,000 – $5,000

- Advanced models: $5,000 – $20,000

Additional Costs to Consider

When budgeting for a bending machine, consider the following additional costs:

1. Maintenance and Repairs

Regular maintenance is essential to keep the machine in good working condition. Factor in the cost of spare parts and service.

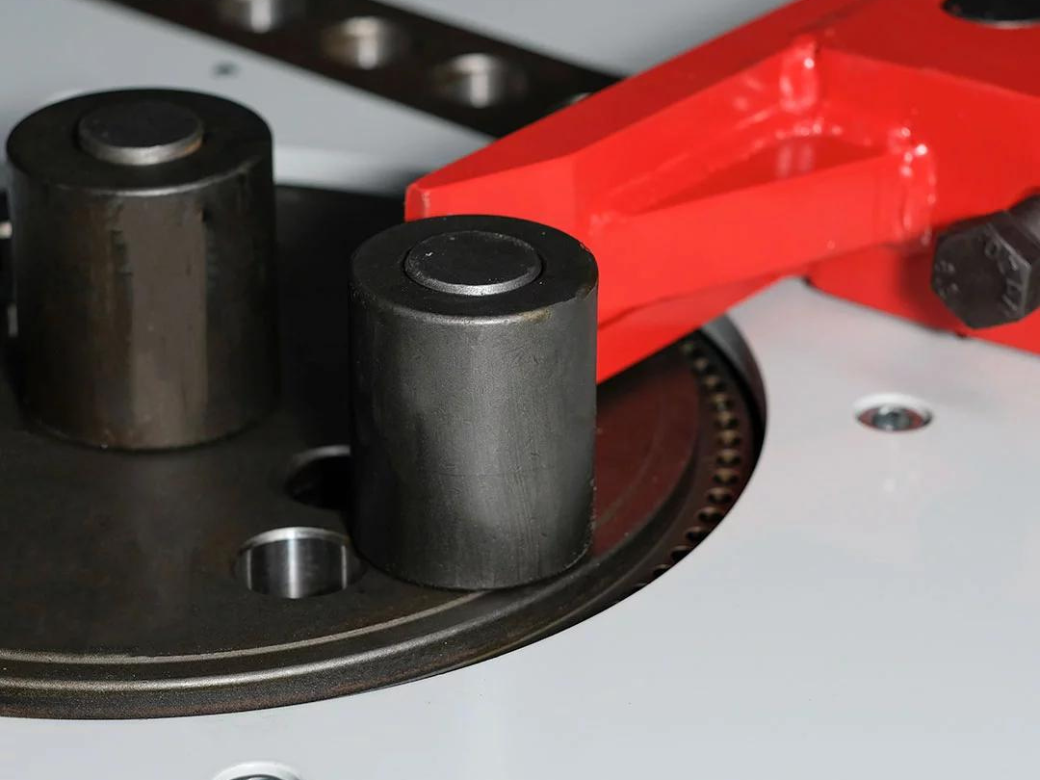

2. Tooling

Additional tooling such as dies and rollers might be required for different bending tasks. These can add to the initial cost.

3. Training

Operators may need training to use advanced machines, particularly CNC models. Training programs can add to the overall expenditure.

4. Installation and Setup

Some machines require professional installation and setup, which can incur additional costs.

Conclusion

The cost of a bending machine varies widely based on its type, capacity, and features. Manual machines are the most affordable, while CNC machines represent the higher end of the spectrum due to their precision and automation capabilities. When planning your purchase, consider not just the initial price but also the long-term costs associated with maintenance, tooling, and training. By understanding these factors, you can select a bending machine that best fits your needs and budget.